PISTA® Innovation History

S&L’s experience flows from more than four decades of thorough R&D and 2,700+ PISTA® installations throughout North America and the world.

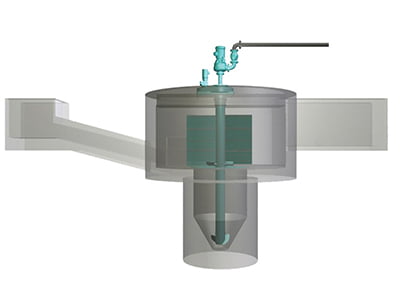

Advancing the Science of Grit Removal Through Comprehensive R&D

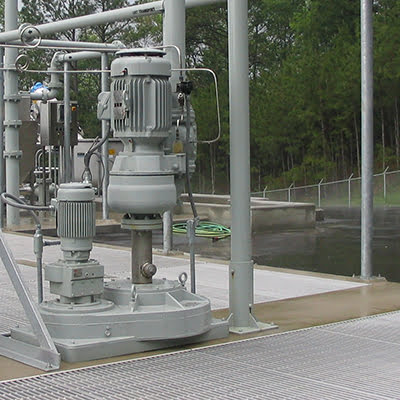

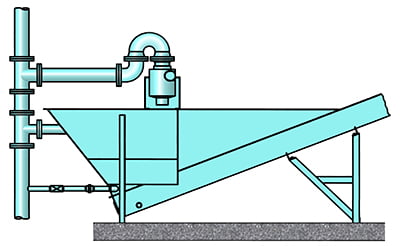

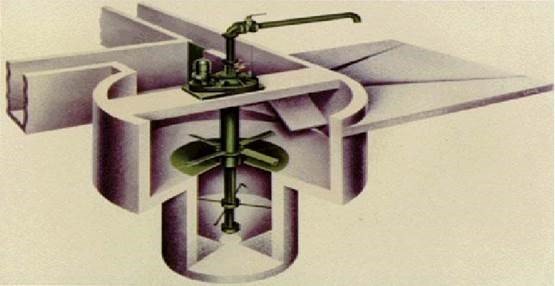

Smith & Loveless knows grit removal and headworks. Our experience flows from more than four decades of thorough R&D and 2,700+ PISTA® installations throughout North America and the world. Along the way, we’ve continued to enhance the complete system with innovations that deliver unparalleled results. With the PISTA® Grit Removal System you receive the finest in system performance backed by the value-added experience and support of Smith & Loveless.

PISTA® Innovation Timeline

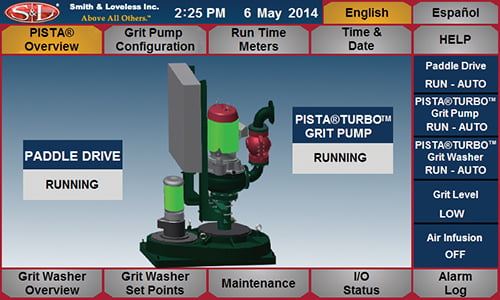

2015

2014

2010

2009

1998

1988

1982

1974

1973