Understanding the pros and cons of different types of grit concentrator technologies can help you choose the right one.

A Look at Grit Concentrator Materials and Construction

Durable PISTA® Grit Concentrators

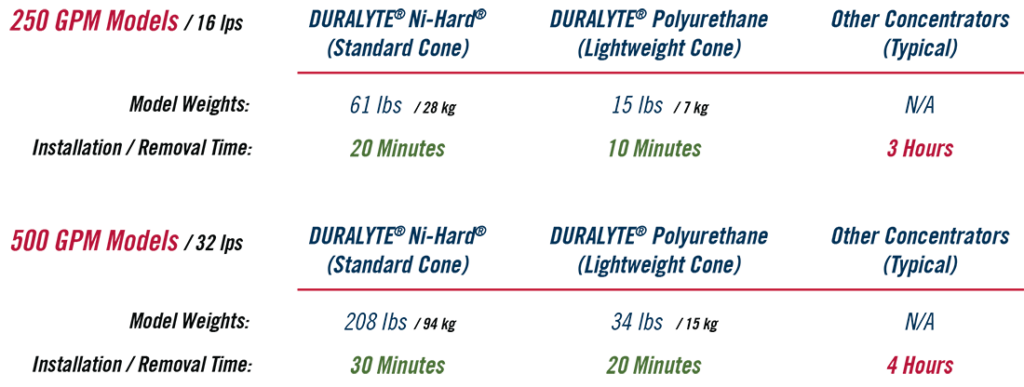

Smith & Loveless 2-Piece PISTA® DURALYTE® Grit Concentrators offer durable and efficient grit concentrator performance with minimal O&M and quicker installation / removal than the competition. The standard 2-Piece PISTA® DURALYTE® Grit Concentrator with Ni-Hard Bottom Cone (starting at 61 lbs / 28 kg) effectively washes collected grit while providing added durability for harsh conditions and heavy grit, like applications with combined sewer systems or high I&I (infiltration and inflow). The 2-Piece PISTA® DURALYTE® Grit Concentrator with Polyurethane Bottom Cone is lightweight (starting at 15 lbs / 7 kg) and even easier to install or remove than the standard design. Both bottom cones are designed with a minimum thickness of 1.25” (3.2 cm) in high wear areas and feature a large discharge plain end grit outlet of 5.5” (14 cm) to minimize clogging. Both systems are available in standard 250 and 500 GPM models / 16 and 32 lps.

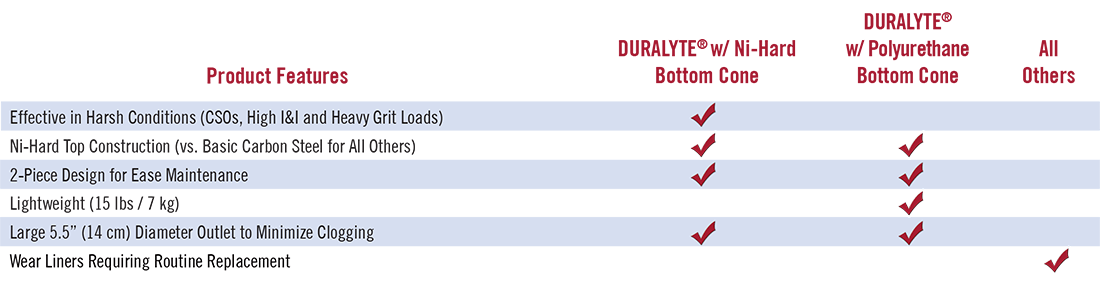

Features & Benefits

- Ni-hard bottom provides added protection against CSOs, high I&I and heavy grit loads

- Poly-urethane bottom easy to install / remove

- Effectively washes collected grit with less than five percent putrescible material

- Large discharge orifice minimizes clogging

- No wearing parts or liners for simple O&M

DURALYTE® w/ Ni-Hard Bottom Cone (Standard)

DURALYTE® w/ Polyurethane Bottom Cone (Lightweight)

Installation and Removal Times / Model Weights

Why Concentrate?

PISTA® DURALYTE® Grit Concentrators effectively function as a primary grit washing and dewatering device, separating the pumped flow into basic components of water, organics and grit. Working in concert with the standard PISTA® Grit Screw Conveyor or premium PISTA® TURBO™ Grit Washer which the concentrator snugly positions above and discharges into, PISTA® DURALYTE® Grit Concentrators overall performance achieves greater than 95 percent removal of the residual organic material.