Learn more about the leading grit removal system in the water industry.

The Highest Grit Removal Efficiency

The Leading Grit Removal System

The Leading Grit Removal System

Hydraulic vortex design with internal baffle design and flat-floor is what makes the PISTA® 360™ completely unique from all other systems, which rely on less efficient settling properties and larger tank sizes. The key to removing grit in wastewater streams — efficiently and cost-effectively — is properly managing flow velocity entering and inside the chamber.

With the lowest life cycle costs in the industry, the PISTA® 360™ delivers tremendous value for plant investment. The PISTA® 360™ with V-FORCE Baffle™ rises above all other grit removal systems in these critical areas:

Utilizes Hydraulic Removal vs. Settling Methods

Inside the grit chamber, the PISTA® design causes grit to be hydraulically swept across the flat (not sloped) chamber floor toward the center opening. The chamber geometry with internal baffling — not the center propeller — is what induces the vortex action and maintains ideal velocity. The low-energy propeller’s primary function is to assist in drawing the grit into the grit hopper and lift and separate the lighter organics.

Superior Grit Removal Efficiency

95% of grit particles down to 105 microns (140 mesh) is the industry’s best against the true grit that causes headaches for any plant operation.

Lower Total Installed & Energy / Utility Costs

Typically smaller tankage – resulting in significantly less concrete for installation – and considerably less power and utility water requirements.

Unequaled Innovation, Experience and R&D

No company has dedicated more to successful grit removal than S&L. Decades of R&D, continual new product innovations backed by 2,600+ installations, the most of any grit removal system supplier.

PISTA® 360™ with V-FORCE BAFFLE™ Benefits

Design & Installation Advantages with V-FORCE Baffle™ Technology

The V-FORCE Baffle™ eliminates the downstream channel required in conventional vortex systems – This contributes to lowering the overall footprint and installation costs.

The V-FORCE Baffle™ eliminates need for downstream flow control device – Reduces overall design and installation costs.

As stated above, the inclusion of the V-FORCE Baffle™ can reduce the number of total units required based on design and peak flow data – Reduces overall design and installation costs

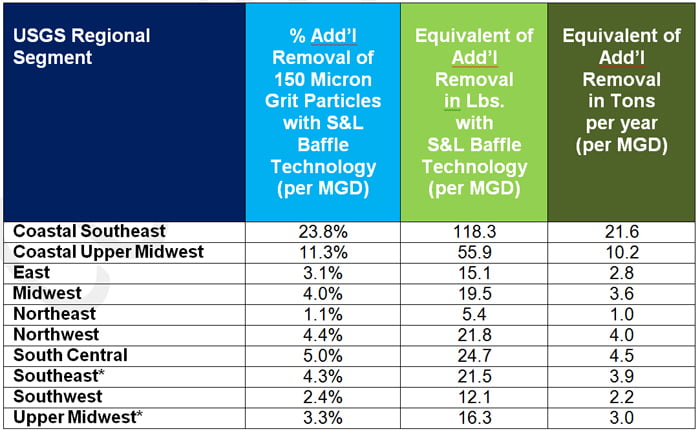

Depending on project flows and regional sediment data, the inclusion of the V-FORCE Baffle™ can significantly increase the amount of incoming grit (between 100 – 300 microns / 50 – 140 mesh) removed per million gallons per day of flow, ranging estimated amount of 20 lbs. to 200 lbs. per MGD (2.4 – 24 kg per 1,000 m3/d) of flow.

At right, grit removal differential examples with S&L baffle technology. Consult with S&L for estimates based on your project’s design flow and region.