There are many important factors to consider when designing your next Grit Removal system. Here’s a look at three of the most important: Footprint, Efficiency and Cost.

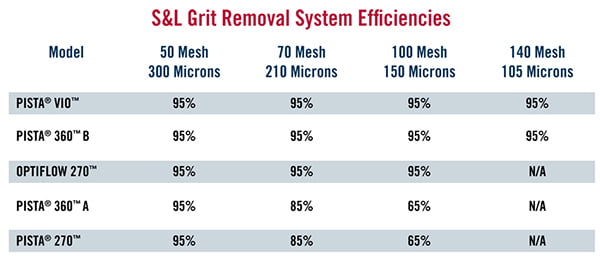

Grit Removal Efficiency

If you know how much grit enters your system, and how much exits your system, you can calculate its Grit Removal Efficiency. This is the percentage of grit the system actually removes from the wastewater stream. Often undersized and not accounting for settling principals, stacked tray, aerated grit chambers, detritors and sloped floor systems are less efficient than S&L’s forced vortex grit chamber with V-FORCE BAFFLE™. It removes 95% of 105 microns across all flows.

High removal efficiencies originate from the PISTA® Grit Chamber’s unparalleled hydraulic design, including its flat chamber floor, patented and low-energy axial-flow propeller.

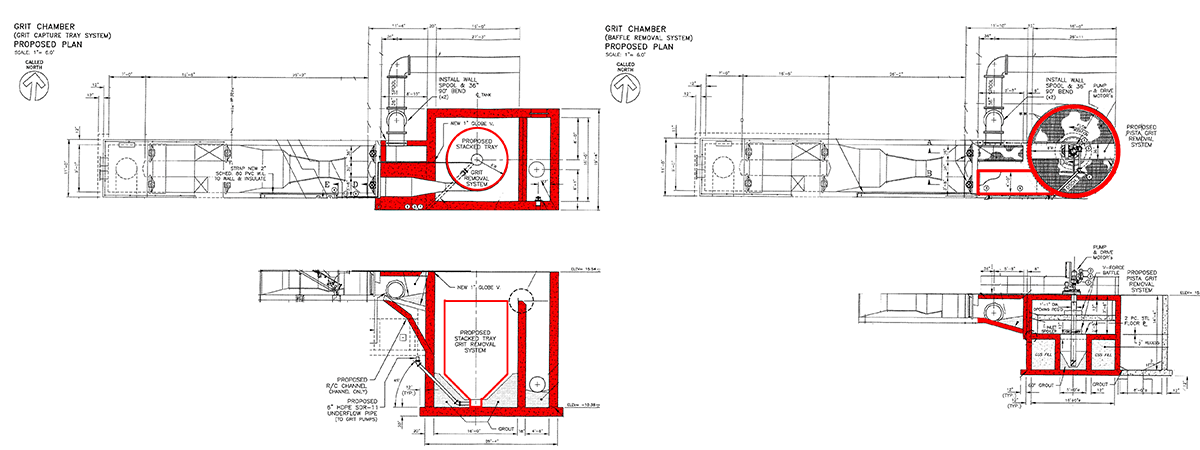

Grit Removal System Footprint

The footprint of your grit removal system cannot be overlooked during the fact-finding and bid phase of your next project. The excavation area and depth should all be considered, because smaller footprints translate into less concrete and smaller construction costs. Compared to stacked tray and sloped floor units, the forced vortex grit chamber with V-FORCE BAFFLE™ by Smith & Loveless has the smallest footprint – both in surface area and depth – resulting in significantly lower construction costs.

Grit Removal System Costs

Purchase price is just one factor when determining the cost of your grit removal system. While not always the least expensive option, the forced vortex grit chamber with V-FORCE BAFFLE™ offers the biggest bang for your buck. And, with both footprint and grit removal efficiency effecting the cost of your grit removal system, S&L’s system is the clear choice for your next grit removal project.